More and more people enjoy making various freeze-dried foods using freeze dryers. So, what components make up a freeze dryer, and how do these components work? Let’s explore the working principle of freeze dryers.

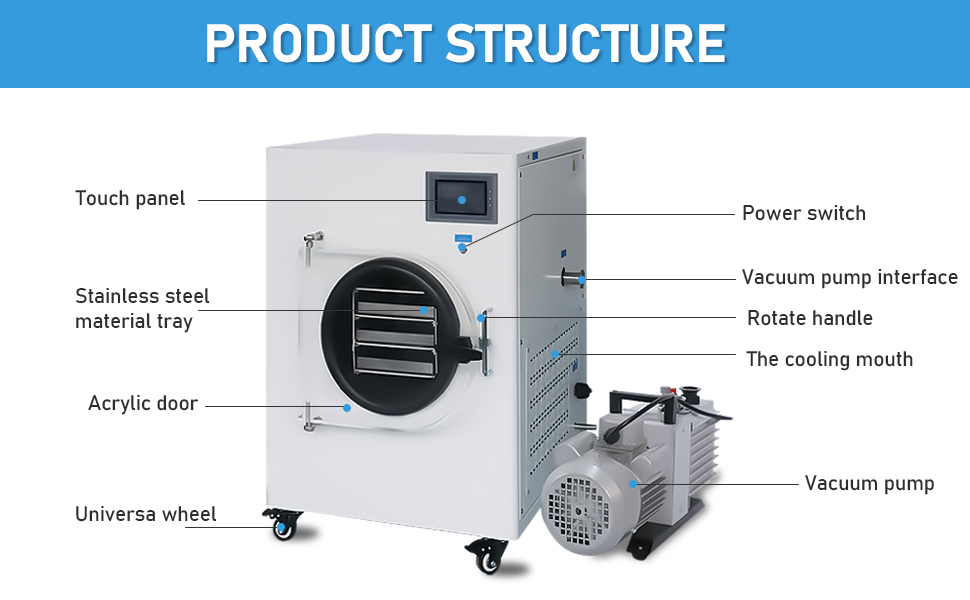

Components of a Freeze Dryer

Vacuum Pump:Used to create a low-pressure environment during the freeze-drying process, allowing moisture to sublimate directly from solid to gas.

Freezing System:Used to quickly freeze the food to the required temperature, usually includes a refrigeration unit.

Heating System:Provides heat during the drying phase to promote moisture sublimation. Home freeze dryers use electric heaters.

Control Panel:Used to monitor and control the entire freeze-drying process, displaying parameters such as temperature, pressure, and time, allowing users to set and adjust.

Cold Trap:Used to capture water vapor released from the sample during sublimation.

Trays:Used to place the food to be freeze-dried. Home freeze dryers have multiple trays to handle more food at once.

Protective Devices:Used to prevent failures such as overheating, overcooling, and overpressure, ensuring the safety of the equipment.

Outer Shell:Protects the internal components, providing a clean and safe operating environment.

Working Principle of a Freeze Dryer

The working principle of a freeze dryer is to use a low-temperature vacuum environment to allow the moisture in the food to sublimate directly from solid to liquid, thereby perfectly retaining the nutrients in the food while removing moisture. The specific process can be divided into three steps:

Freezing Phase

The freezing chamber of the freeze dryer, under the action of the refrigeration system, quickly freezes the material to a low temperature (usually between -30°C and -60°C), ensuring that the moisture in the material is completely frozen.

Vacuum Phase

The vacuum pump gradually extracts the air from the freezing chamber, lowering the pressure until it reaches a vacuum state. In this environment, the moisture in the food begins to sublimate.

Sublimation Phase

In a vacuum environment, the heating system gradually heats the frozen material, accelerating the speed at which ice changes directly from solid to gas. This process requires precise control of the heating rate and temperature to ensure a stable sublimation process. Additionally, the condenser starts working outside the frozen water to capture the water vapor produced by sublimation and condense it into liquid water, which is then discharged from the system.

Maintenance and Usage Notes for a Freeze Dryer

Regular Cleaning

- Clean Trays and Shelves: Use warm water and a mild detergent to clean the trays and shelves, ensuring all food particles are removed.

- Clean Cold Trap: Regularly remove ice or condensed water accumulated in the cold trap to maintain its efficiency.

- Clean Vacuum Pump Oil: If the vacuum pump is oil-lubricated, regularly change the vacuum pump oil.

Check Seals:Regularly check the door seals and the vacuum tube seals to ensure there are no leaks. Replace damaged seals as necessary.

Vacuum Pump Maintenance:Follow the user manual’s requirements to regularly check and replace the vacuum pump filters and oil to ensure the normal operation of the vacuum pump.

Freezing System Check:Regularly check the amount of refrigerant and the cooling effect of the system to ensure the normal operation of the freezing system.

Regular Use:When not used for a long time, run the freeze dryer periodically to ensure all components remain in good condition and avoid problems caused by long-term inactivity.

These are the common issues with home freeze dryers. If you want to know more information, feel free to contact us at any time.